The Secret to Long-Lasting Boat Flooring

posted by Ryan Sacksteder on Jun 16th 2025

The Secret to Long Lasting Boat Flooring

Ever notice how your boat’s factory flooring starts to show its age way too fast? Those tired, slippery surfaces that once looked brand new have taken a beating from countless fishing trips, family outings and weekend cruises.

Constant exposure to sun, salt, fish blood and spilled drinks can seriously damage standard, factory fitted flooring.

But what if there was a way to keep your boat’s deck looking showroom fresh for years to come? Well, thanks to the best boat flooring on the market, there is - and it’s not as complicated or expensive as you might think.

Why Most Boat Floors Fail So Fast

Standard boat flooring has three problems: it gets slippery when wet, it’s hard on your body during long days on the water and it just doesn’t hold up well against the elements.

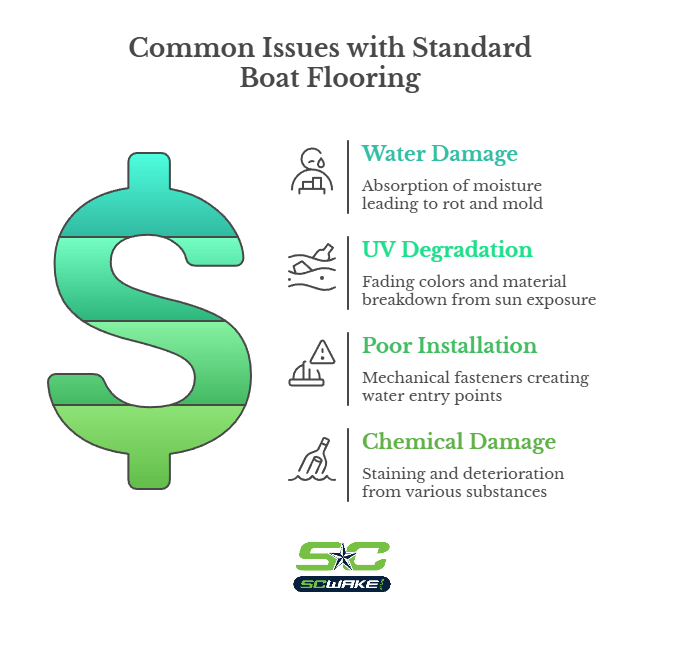

The most common issues with standard flooring are:

Water damage: Traditional materials absorb moisture, leading to rot, mold and structural weakening

UV degradation: Sun exposure fades colors and breaks down material integrity

Poor installation: Mechanical fasteners can create water entry points

Chemical damage: Fish blood, drinks and cleaning agents stain and deteriorate surfaces

Most factory boats come with fiberglass non-skid or moulded patterns that might look fine initially but quickly become a real problem. The texturing wears down in high traffic areas, UV rays cause discoloration and cleaning becomes increasingly frustrating as grime works its way into every groove.

What Is the Best Flooring for Boats?

There’s a reason why closed cell EVA foam boat flooring like SeaDek is becoming so popular with boaters across America. Unlike traditional surfaces, this marine grade material was designed to address all the shortcomings of standard boat flooring.

The closed cell construction means it won’t absorb water, fish blood or spilled drinks. Instead of soaking in and creating stains or odours, all liquids stay on the surface where they can be wiped away. In other words you won’t have any permanent reminders of that mahi-mahi you caught last summer.

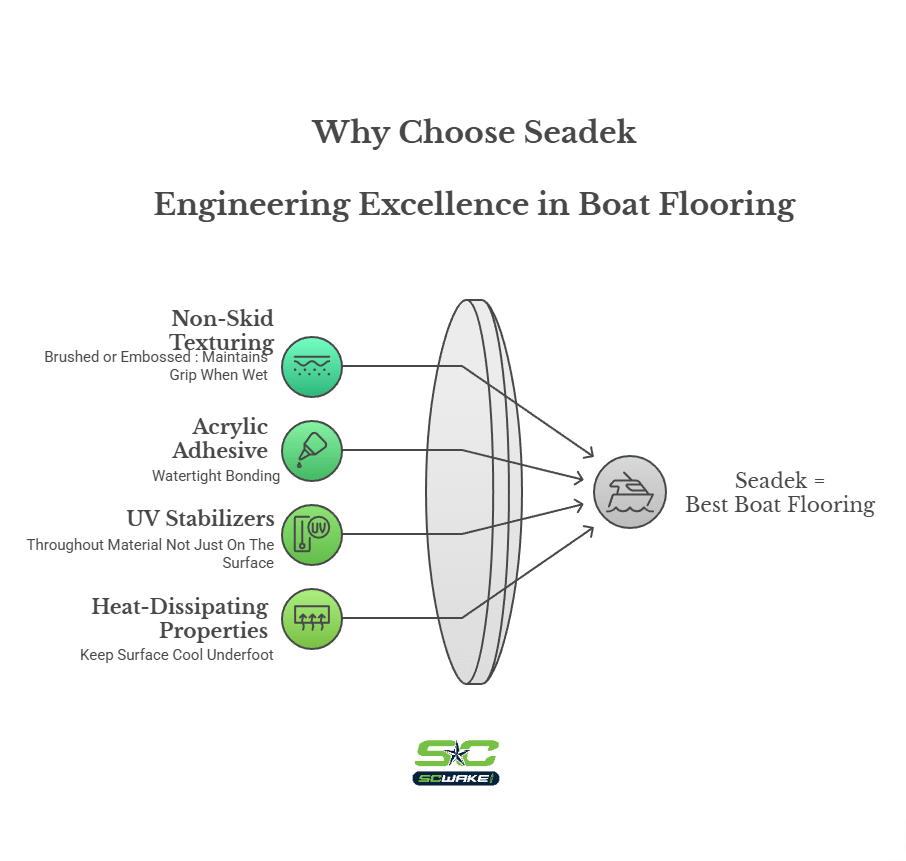

But durability means more than just stain resistance. High quality marine EVA foam maintains its texture and appearance even after years of heavy use. The colour runs throughout the material rather than being a surface treatment so even if minor scratches occur they won’t reveal a different colour underneath.It’s all about the engineering. We’ve created what is arguably the best boat flooring material available through extensive research and development, resulting in the following features:

Engineering Details

-

Non-skid texturing (brushed or embossed) that maintains grip even when wet

-

Acrylic-based pressure-sensitive adhesive that creates watertight bonds

-

UV stabilizers throughout the material, not just on the surface

-

Heat-dissipating properties that keep the surface comfortable underfoot

Pro Maintenance Routine

The real secret to long lasting boat flooring is minimal but consistent maintenance.

Traditional boat surfaces often require harsh cleaners, serious scrubbing and sometimes even sanding or refinishing to keep them looking decent. In contrast EVA foam flooring needs remarkably little upkeep to maintain its appearance and performance.

Regular cleaning with soap and water removes most dirt and grime. For tougher stains or a deeper clean specialty products like SC Wake Boat Juice lift away stubborn dirt without damaging the material. A soft brush helps work the cleaner into the textured surface without excessive scrubbing.

Maintenance Calendar

|

Timeframe |

Task |

|

After Each Use |

Quick freshwater rinse to remove salt and debris |

|

Monthly |

Mild soap and water cleaning with a soft brush |

|

Quarterly |

Deep clean with specialty products |

|

Bi-Annualy |

Full inspection for any lifting edges or damage |

SeaDek Installation

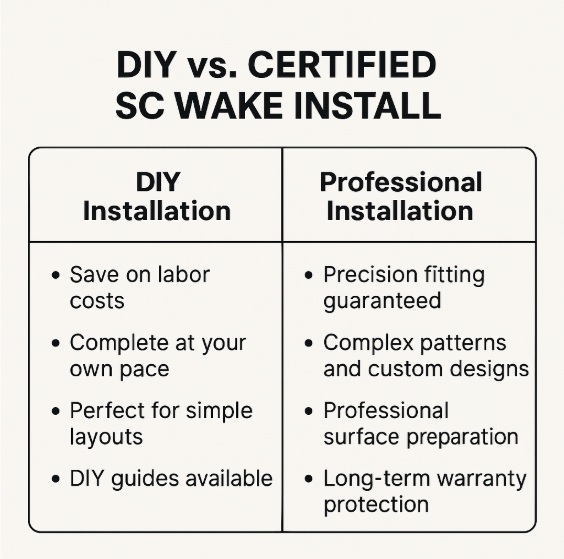

One of the most impressive features of SeaDek flooring is the DIY boat flooring installation process. With an acrylic-based pressure-sensitive adhesive backing it applies directly to your existing deck with no special tools required.

The smart peel-and-stick application means you don’t need to drill holes or use mechanical fasteners. The adhesive creates a watertight bond that prevents moisture from getting underneath the material.

Of course professional installation is also an option for those who want to ensure perfect fit and alignment, particularly for complex deck layouts.

Temperature and UV Resistance: The Hidden Factors

Two often overlooked factors in boat flooring are temperature tolerance and UV resistance. Ask anyone who’s walked barefoot on a dark coloured boat deck in summer and they’ll tell you about the surprising pain of heat soaked surfaces.SeaDek’s closed cell construction provides natural insulation properties. Even darker colours dissipate heat quickly, making the surface more comfortable underfoot during hot days. This temperature regulation wasn’t designed purely for comfort however: extreme heat cycling is a major factor in the premature breakdown of many marine materials.

As for UV exposure - the silent killer of most boat components - quality marine EVA foam includes UV stabilizers throughout the material. This helps prevent the fading, cracking and deterioration that sun exposure typically causes, keeping your deck looking fresh even after countless days under harsh rays.

Choosing Your Upgrade — Quick Checklist

Thinking of upgrading? You’ll want to consider these factors:

Primary use: For fishing boat flooring options, choose an embossed SeaDek texture with maximum noise reduction properties. Family cruisers might benefit from 8mm or thicker options that provide comfort during longer outings.

Climate exposure: In tropical environments, go for lighter colours like Storm Gray or Cool Gray that resist heat absorption while providing excellent UV protection. Saltwater users should consider 6mm dual colour options for superior durability.

Comfort needs: Standing all day fishing? The 13mm “Cushion” thickness dramatically reduces fatigue. Casual weekend boaters might find that lightweight boat flooring like the 5mm single colour provides sufficient comfort with maximum durability.

Appearance: In addition to basic colours, consider custom routing patterns that match your boat’s style. Faux teak patterns offer a classic look, while diamond or hexagon patterns provide a modern aesthetic.

Installation preference: For DIY installation, the 5mm or 6mm sheets with minimal cutouts are easiest to work with. Complex layouts with extensive cutouts benefit from SC Wake's professional boat flooring installation service.

Budget: While 5mm single colour options offer the most affordable entry point, the 6mm two colour options deliver the best balance of price and performance for most boaters.

The Aesthetic Element

Looks matter when it comes to boat flooring ideas. Your vessel’s visual appeal reflects your personal style and the pride you take in your watercraft.

With numerous boat flooring colors and design options available, from solid colours to custom patterns, you can create a look that’s uniquely yours. Unlike painted surfaces or gelcoat, these colours maintain their appearance and vibrancy year after year without fading or chalking.The textured surface options, either brushed or embossed, provide both functional grip and visual appeal. Some boaters even go for custom routing designs like faux teak, fish scales or geometric patterns that add character to their vessel.

Real-World Lifespan

Under normal conditions, the best boat flooring - like SeaDek’s quality EVA foam product - typically lasts 5-7 years, though many boat owners report even longer lifespans with proper care. Factors that affect the lifespan of your new boat flooring include:

-

How often the boat is used

-

Whether it’s stored indoors or constantly exposed to the elements

-

The climate in your region

-

How well it’s maintained

With proper storage and occasional cleaning, many boaters see 7+ years of service from their SeaDek flooring, far outlasting factory surfaces that often show significant wear within 2-3 seasons.

Expected Lifespan Comparison Table

|

Flooring Type |

Expected Lifespan |

Common Failure Points |

|

Marine Carpet |

3-5 years |

Mold, staining, separation |

|

Teak |

7-10 years |

Wood rot, fastener corrosion |

|

EVA Foam |

5-7+ years |

Edge lifting, color fading |

SeaDek: The Smart Investment

The math is simple. When you consider the cost of refinishing or replacing conventional flooring (not to mention the safety benefits of non-slip surfaces and comfort during long days on the water), premium EVA foam flooring is a smart investment in your boat’s future, not to mention your enjoyment of it.

Ready to see how custom boat flooring can transform your pride and joy? Request a quote to learn how easy it is to upgrade to flooring that truly lasts.

Your boat deserves flooring that works as hard as you do... and looks good doing it!

FAQs

How long does the best boat flooring typically last?

5-7 years, though many boat owners report even longer lifespans with proper care.

Can boat flooring be installed over existing surfaces?

Yes, quality marine flooring adheres to most clean, stable surfaces, including fiberglass, aluminum and properly prepared wood.

What’s the best way to clean boat flooring?

Soap and water for regular cleaning, specialty products for deeper cleaning. Avoid harsh chemicals that can break down UV protection.Longest lasting?

EVA foam